OUR PARTNERS

We Strongly Maintain Quality Partners, To give Best for our Customers

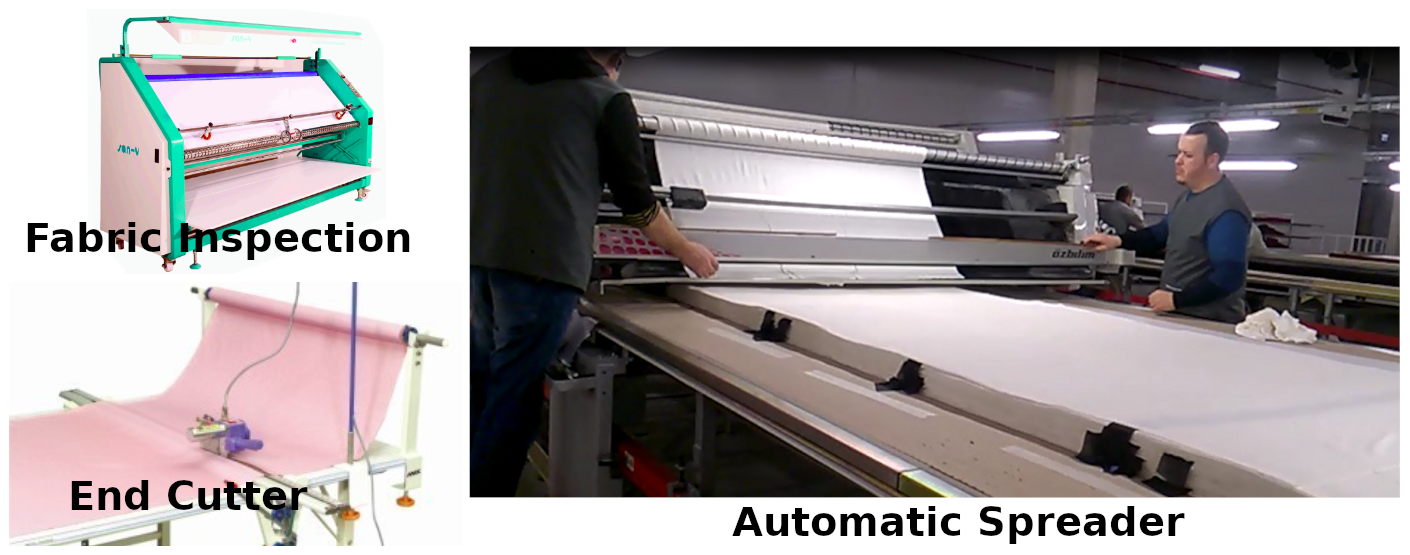

Fabric Inspection is an important aspect followed prior to garment manufacturing to avoid rejects due to fabric quality and facing with unexpected loss in manufacturing. Fabric inspection is done for fault/defect rate, fabric construction, fabric weight, shrinkage, end to end or edge to edge shading, color, hand feel, length/width, print defect and appearance. Fabric inspection ensures to minimize the rejection of cut panels or rejected garments due to fabric faults. Cutting inspected and approved fabric ensures not only finished garment quality but also reduce rejects, improves efficiency and timely deliveries.

Fabric spreading is very important part of the production process because it is basic for obtaining a high quality final product. Spreading is the process of unwinding large rolls of fabric onto long, wide tables in preparation for cutting each piece of a garment. The number of layers of fabric is dictated by the number of garments desired and the fabric thickness. Spreading can be done by hand or machine, depending upon the fabric and cutting technology, up to 200 layers of fabric may be cut at one time. Fabric Spreading Machines are used for bulk production.

We Strongly Maintain Quality Partners, To give Best for our Customers